Healthcare

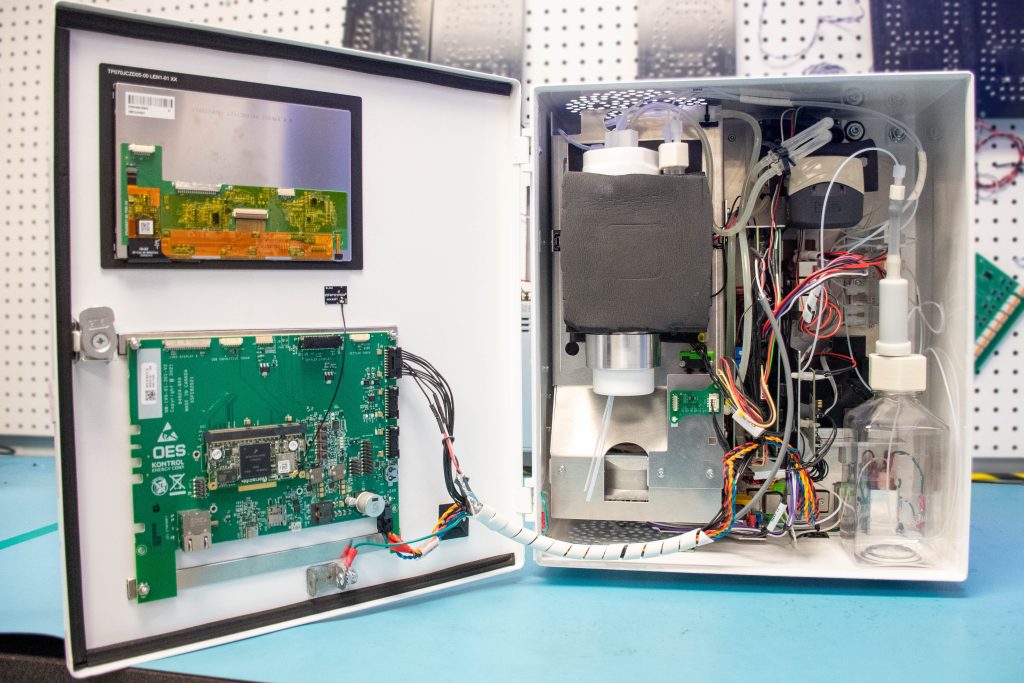

Collaborating with prominent companies, we play a crucial role in bringing patient-wellness focused products and vital hospital equipment to market. Recognized as a sought-after partner in the health industry, we specialize in providing printed circuit board assemblies and box build services. Our offerings extend to a diverse range of applications, encompassing the production of components for hospital bed controllers, programmable breathing simulators, and radiotherapy systems. With a commitment to precision and reliability, we contribute to the development and delivery of cutting-edge solutions that enhance patient care and support critical functions within the healthcare ecosystem.

OES emerges as a highly dependable and esteemed Electronic Manufacturing Services (EMS) partner in the Healthcare industry. With a proven track record of delivering cutting-edge solutions and an unwavering commitment to excellence, OES excels in providing tailored electronic manufacturing services that align with the unique and stringent requirements of the healthcare sector. The company’s state-of-the-art facilities and advanced technologies ensure the production of high-quality, reliable, and medical devices with electronic components and systems vital for healthcare applications. Recognizing the significance of precision, and compliance within the healthcare sector, OES’s dedicated team of experts consistently surpasses these expectations. Through a collaborative approach and a steadfast focus on innovation, OES plays a pivotal role in advancing healthcare technology like hospital bed controllers, programmable breathing simulators, and radiotherapy systems and ensuring the reliability of electronic systems crucial for patient well-being and medical advancements.

Precision and accuracy in Electronic Manufacturing Services (EMS) play a pivotal role in the healthcare industry due to the critical nature of the applications involved. In healthcare operations, electronic components and systems must function flawlessly under challenging conditions, often in high-stakes environments where the margin for error is minimal. Any deviation from precise specifications can have severe consequences, compromising the effectiveness and reliability of life-saving equipment. The precision in manufacturing ensures that electronic components meet exacting standards, promoting consistent performance and interoperability. Accurate assembly and calibration are essential to guarantee that healthcare systems operate as intended, contributing to the overall success and safety of medical procedures. Moreover, precise EMS work is crucial for meeting stringent quality control and compliance standards set by healthcare regulatory bodies, reinforcing the reliability and resilience of electronic systems in the face of diverse challenges and potential threats. The emphasis on precision and accuracy in EMS for the healthcare industry underscores its significance in safeguarding patient well-being and medical effectiveness.